Area of automation, digitalization and industrialization of processes

“Technology as a driver of change”

Through the automation area, the ARRAM group, in strategic alliance with DEUSER brings control, efficiency, and innovation solutions to production processes. Thanks to digitalization and Industry 4.0, we turn data into decisions. With our process industrailization consultancy, we help to build the factory of the future.

WITH OUR CONSULTANCY IN PROCESS INDUSTRIALISATION, WE HELP BUILD THE FACTORY OF THE FUTURE.

In a world where technology is advancing by leaps and bounds, industries need to be more efficient in their production processes to be more competitive in an increasingly global market. To this end, ARRAM Consultores, in alliance with DEUSER, offers from its Automation, Digitalisation, and Industrialisation of Processes area, the following services:

AUTOMATION

From the ARRAM group in alliance with DEUSER we are committed to the implementation of automatic systems to increase production, reduce mistakes, improve the safety of production processes, and increase their efficiency.

Consultancy, Environmental Procedures, and Specific Studies

![]() CONTROL SYSTEMS.

CONTROL SYSTEMS.

Design and programming of control systems.

![]() AUTOMATION OF PRODUCTION LINES.

AUTOMATION OF PRODUCTION LINES.

Study of process improvements, synchronization solutions/product flows in line. Control of installations.

![]() HANDLING AND END-OF-LINE SYSTEMS.

HANDLING AND END-OF-LINE SYSTEMS.

Palletising systems, handling applications, processing line upgrades.

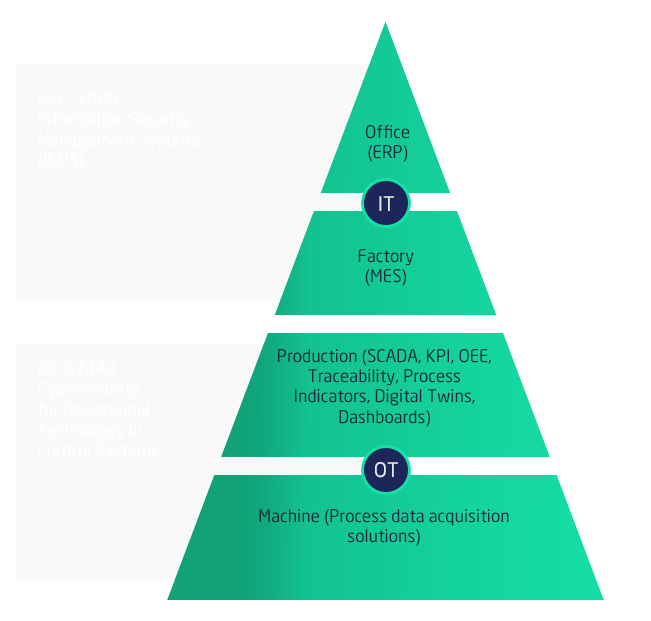

DIGITALISATION

At ARRAM, in alliance with DEUSER, we are moving towards Industry 4.0 and IIoT. From the use of Digital Twins to eliminate uncertainty in decision making, to the development of applications that enable us to efficiently manage our production process, OEE indicators, control notebooks, traceability, SCADAs, etc.

![]() ACQUISITION:

ACQUISITION:

Process data acquisition systems.

![]() DEVELOPMENT OF APPLICATIONS.

DEVELOPMENT OF APPLICATIONS.

Control system supervision systems (SCADA), traceability registers, OEE (Overall Equipment Efficiency) (overall effectiveness of production equipment), KPI indicators, dashboards.

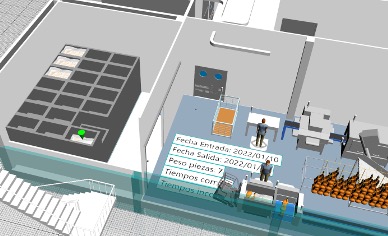

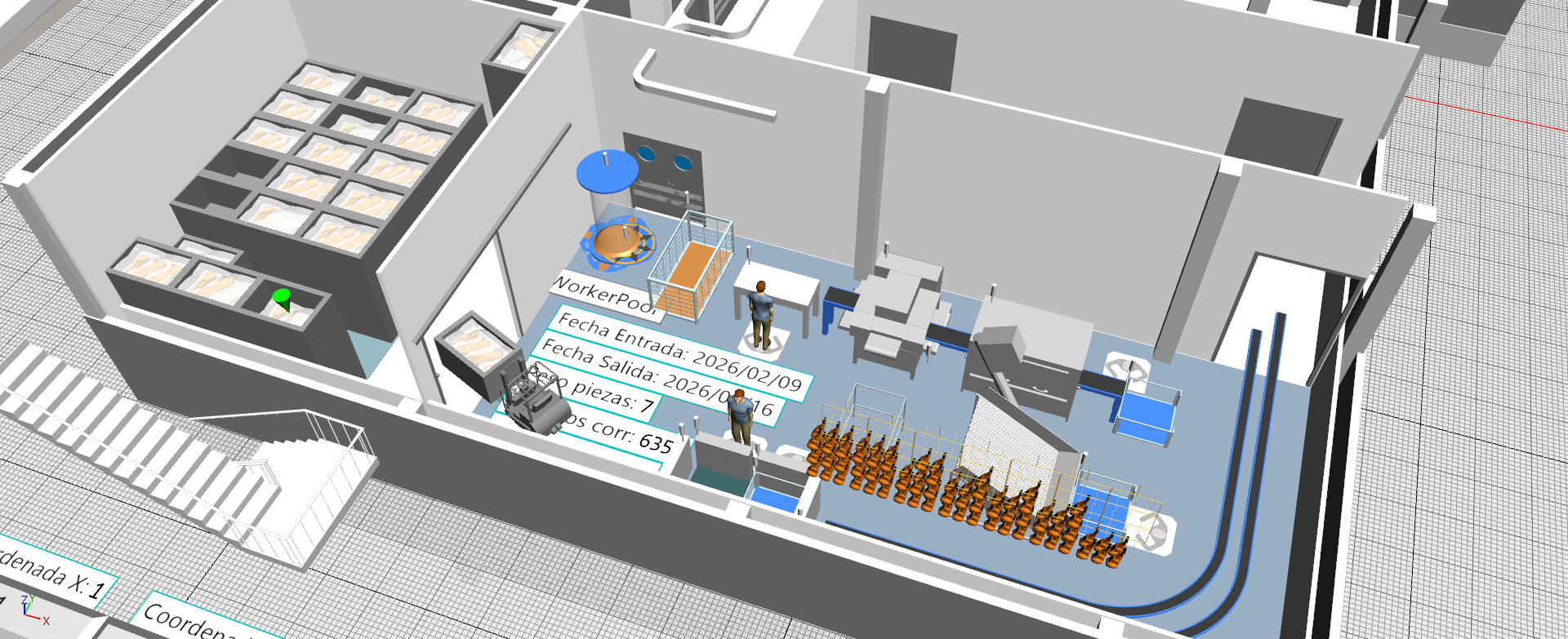

![]() DIGITAL TWINS.

DIGITAL TWINS.

Identification of critical points in the processes and simulation of the production to see how the improvement systems proposed are affected.

CONSULTANCY IN INDUSTRIALISATION OF PROCESSES

The passage of a process from its definition phase using laboratory techniques or pilot experiments to its industrialization phase is a challenge that needs to be faced from a multidisciplinary perspective and a wide knowledge of industrial environments.

DETAILED STUDY OF THE PROCESS. Defined by the client and its associated parameters.

DETAILED STUDY OF THE PROCESS. Defined by the client and its associated parameters.

DETERMINATION OF STANDARDS. Applicable to each area of the process.

DETERMINATION OF STANDARDS. Applicable to each area of the process.

IDENTIFICATION OF TECHNOLOGIES. And global approach to the installation.

IDENTIFICATION OF TECHNOLOGIES. And global approach to the installation.

SELECTION OF MANUFACTURERS/SUPPLIERS. Of specific solutions for the selected Process and technology.

SELECTION OF MANUFACTURERS/SUPPLIERS. Of specific solutions for the selected Process and technology.

IDENTIFICATION OF RELATED SECTORS/PROCESSES in the absence of specific solutions

IDENTIFICATION OF RELATED SECTORS/PROCESSES in the absence of specific solutions

ASSEMBLY OF SOLUTIONS. Individuals until the entire process is in its entirety.

ASSEMBLY OF SOLUTIONS. Individuals until the entire process is in its entirety.

SOLUTION VALIDATION. By simulation with digital twin technology.

SOLUTION VALIDATION. By simulation with digital twin technology.